Why waterproofing?

Waterproofing works are essential for civil engineering projects, as they protect the structures from water damage and ensure their durability and performance. Waterproofing works involve the application of various materials and techniques to prevent water intrusion into the building components and protect them from water-related damage. In this blog post, I will discuss some of the common types and methods of waterproofing works in civil engineering, as well as their advantages and disadvantages.

One of the most widely used types of waterproofing works is cementitious waterproofing, which is the easiest and most economical method of waterproofing in construction. Cementitious waterproofing materials are readily available from suppliers of masonry products, and they are easy to mix and apply. Cementitious waterproofing works by forming an impervious barrier over surfaces of foundations, roofs, walls, and other structural members. The applications of cementitious waterproofing are mainly in the internal wet areas, such as toilets, bathrooms, kitchens, and basements. However, cementitious waterproofing is not suitable for exposure to sunlight, as it does not undergo contraction and expansion, and it may crack under thermal stress.

Another common type of waterproofing works is liquid waterproofing membrane, which consists of a primer coat and two topcoats. The application of the coatings is by spray, roller, or trowel. The liquid membrane cures into a rubbery coating on the wall, which offers more flexibility and elasticity than the cementitious type of waterproofing. The liquid waterproofing membrane can also withstand higher temperatures and UV rays, making it suitable for external applications. The liquid waterproofing membrane can be made of different materials, such as polymer-modified asphalt, polyurethane, or acrylic-based polymers. The advantages of liquid waterproofing membrane are its high resistance to water, chemicals, and abrasion, as well as its ability to bridge cracks and accommodate movements. The disadvantages are its higher cost, longer curing time, and the need for skilled labor and equipment.

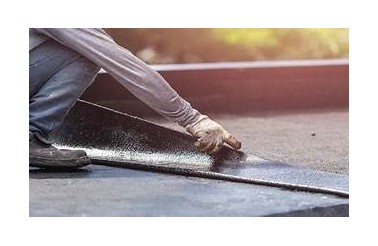

A third type of waterproofing works is bituminous waterproofing, which is made of bitumen-based materials, such as asphalt or tar. Bituminous waterproofing can be applied in the form of a coating or a membrane. Bituminous coating is a flexible protective coat that can adhere to various surfaces, such as concrete, metal, or wood. Bituminous membrane is a sheet of bituminous material that is reinforced with fibers, such as polyester or fiberglass. Bituminous waterproofing works by creating a watertight seal over the surface, preventing water penetration and corrosion. Bituminous waterproofing is commonly used for roofs, foundations, and basements, as it can withstand weathering and aging. However, bituminous waterproofing is also susceptible to cracking, shrinking, and melting under high temperatures, and it may emit harmful fumes and odors.

These are some of the types and methods of waterproofing works in civil engineering that can help protect the structures from water damage and ensure their longevity and functionality. Depending on the project requirements, budget, and site conditions, different types and methods of waterproofing works can be chosen and combined to achieve the best results. For more information on waterproofing works in civil engineering, you can visit the following websites: The Constructor, Civil Engineering Portal, and Engineering Civil. Thank you for reading this blog post, and I hope you found it informative and useful.